Profit, for any company, is the primary goal, and with a business that does not initially have investors or financing, profit may be the corporation’s only capital. Without sufficient capital or financial resources to sustain and run, business failure is imminent.

It’s true that stalled profit is the unwelcome scenario for every business. However, there will be a time the company has to cope with such a situation. And rather than panicking or overthinking, taking a step back to look at your supply chain management can be an effective solution to this issue.

1. Reasons for stalled profit and its core relation with supply chain management

Poor Customer Service by inefficient data tracking systems and poor supply chain visibility

Today, consumers have so many options that they can turn to if they encounter a bad service experience. Thus, the shrinking customer base results in fewer sales, which leads to a direct loss of revenue.

Normally, low customer satisfaction comes from ineffective problem-solving and poor response. Without an effective data tracking system, business takes hours to identify customers problems and even some days to handle some easy tasks like finding the customer’s ID. Especially for the shipping industry or FMCG companies, with the enormous amount of customer’s database information, the inefficient data tracking system might cause lost information, miscommunication.

Besides, a process to finish an order requires coordination between many people; in some cases, it has seen up to 11 different people involved. As it is disjointed and time-consuming, if there’s no visible chain of custody, it’s easy for things to get lost in the shuffle

High supply chain cost results in high product prices and this leads to the reduction of customers

Supply chain activities come with a lot of infrastructure, overhead and staffing costs. Such operating and capital expenses can quickly add up and significantly impact a company’s profitability…if not handled properly. Moreover, a supply chain costs can make up for around 55% of the total product cost, therefore, with a higher supply chain cost and also the operational cost, it is extremely difficult for a company to keep their product price low [1]. Image Source

This issue is even more crucial in recent days as consumption and production are growing enormously fast. Companies need to become more and more competitive in order to sustain in the market, and the only way to do so is to provide a reasonable price. Not having a competitive price, businesses cannot be flexible and adaptable to offer different prices to different customers.

Short-Sighted Risk Management in Supply Chain can cause business disruption

The rapid change in the market, rooting from various sources such as consumer demands, Supplier issues, Supply shortages, would pose a threat to the operations. Plus, the supply chain involves many processes and stages that are intertwined. Therefore, a small number of problems that occur in some steps can delay the whole workflow. Without a thorough contingency plan, disruption in the Supply Chain is likely to happen and obviously, the damage is severe.

It has been recorded that 440 companies from Fortune’s 1955 list that failed and disappeared had one thing in common [2]. They all had weak supply chain management. Thus, if the company’s profit is stalling, you now have a clue what can be improved first.

2. How to fix the situation - Use money to make money

Profit stalling is scary, but rather than trying to save money by firing labor to cut down costs, opening to new innovation is the key to survival. And here are some new approaches that worth investing in:

Order Tracking Fulfillment software or Product Information Management Software to raise customers satisfaction

It is reported that 50% of customers increase their purchasing with a brand after a positive customer dish experience [3]. A good customer service requires a 4 “Right”, Right product assortment & quantity, Right Location, Right Delivery Time, Right After Sale Support. In order to do that, the above software could be useful as it provides a circle - end to end solution, from the time the products are still in the warehouse until it is delivered to the hand of the customers.

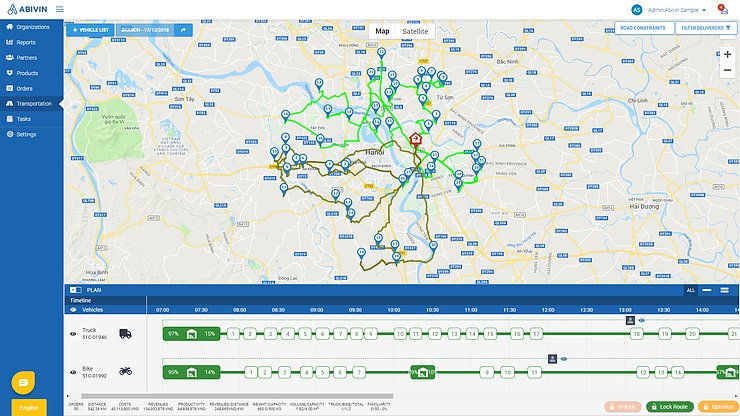

TMS or WMS to detect inefficiencies and cut down redundant cost

In the situation when profit stops growing, it is crucial to review every step in the process to improve or eliminate unproductive phases. For that purpose, a TMS (Transport Management Software) and WMS (Warehouse Management System) which have a number of highlight features are beneficial for the supply chain to cut down unnecessary expenses.

- TMS: A case study has shown that after implementing TMS, CAGO - an American agricultural equipment manufacturer has cut down on freight cost by 18% within a year. Besides, in China and America, these tactics have decreased inbound logistics cost by 28% and boost performance by 25% [4].

- WMS: Integrated with the core logistics software, WMS can help reduce transportation expenses thanks to increases in shipping accuracy. Its functions embrace anything from the order and inventory maintenance to tracking transportation unit appointments and status.

Forecasting

It is impossible to foresee the future but it is feasible to predict the upcoming trend in order to mitigate risk. However, many logistics managers consider it a challenging task. That’s when a demand forecast software comes in handy. A good demand forecast software can give users a more precise market trend prediction so that businesses can act accordingly rather than being passive.

3. Conclusion

No business can survive for a significant amount of time without making a profit. Measuring a company's profitability, both current and future, is critical in evaluating the company. As the supply chain plays such an indispensable role in the whole operation that nowadays 80% of companies in the world now prioritize protecting their supply chain [5]. Making sure your supply chain is on track is a key to success for any business.

Want to optimize your supply chain, contact us for consultation

References:

[1]_https://www.researchgate.net/publication/272857284_The_Impact_of_Supply_Chain_Cost_on_the_Price_of_the_Final_Product

[2]_https://www.researchgate.net/publication/333855582_Managing_Operations_Throughout_Global_Supply_Chains

[3] https://blog.hubspot.com/service/importance-customer-service

[4] https://innovecs.com/blog/logistics-software-reduces-cost-of-transportation [5] https://abivin.odoo.com/blog/blog-5/how-an-inefficient-supply-chain-can-kill-an-fmcg-business-1564

Profit Is Stalling? Take A Look At Your Supply Chain!